By Donna Motley, Vice President of Claims

Welcome to the New Year – 2018! Do people still make New Year Resolutions? To lose weight, get in shape, become more active, volunteer in the community, etc.? These are all wonderful resolutions and can result in a better, more satisfying and hopefully, longer lifespan. But there are more benefits than those listed. Being in better physical shape, healthy eating, proper sleep patterns carry over to the employment atmosphere and aid in avoiding accidents and injuries. Being more alert, having more energy, a more positive attitude can provide long lasting results in the workplace. And, should an injury occur, it may be a minor, less serious injury. Statistics have shown, the better the condition of your mind and body, the quicker recovery from an injury or surgery. I’ve written in the past about how “co-morbidities” can affect an injury and recovery. Prescriptions and physical therapy that would aid in recovery may be limited because it would interfere with other health conditions and treatment.

Whether you believe in “Seasonal Affective Disorder” or not, the Mayo Clinic describes “Seasonal Affective Disorder” as a type of depression, but it is more than that. It saps energy levels, can make a person feel moody. Old schoolers would call this the “Winter Blues”. Symptoms can be depression, low energy, a loss of interest in activities normally enjoyed, problems sleeping (that can result in “oversleeping”), a change in appetite (typically craving carbohydrates) resulting in weight loss or weight gain, and difficulty concentrating. All these symptoms can have a negative effect on a person’s professional, social and recreational life. The main, acknowledged cause of Seasonal Affective Disorder – SAD – is believed to be related to decreased sunlight. Decreased sunlight is thought to disrupt your body’s internal clock, drop the serotonin level which is a brain chemical that affects mood, and disrupts the body’s balance of melatonin levels. Let’s face it, we live in Michigan, not the sunniest of places ! The majority of us probably suffer from SAD in one form or another. Do you ever notice how much happier people seem on a sunny day – even in winter? The mere fact that the sun is shining seems to make things more bearable. According to the Mayo Clinic, there is a reason why.

So, if your general health is poor, you have poor eating habits, don’t exercise, don’t get enough sleep or sleep excessively, you have a lack of energy or just feel kind of “down in the dumps” and you add a lack of sunshine to the list, is it a wonder accidents happen? Some things we cannot change – but there are things we can have control over – particularly how we live our life and what we do with our bodies. It’s tough to get through winter in Michigan, people typically get the “after holiday blues”, so now is the time to think positive, make positive choices. Even small changes in a positive direction can snowball into big changes in every aspect of your life.

If a healthy, alert person sustains no work injury; just think of the positive impact that can have on the work environment; the employee is happy, the employer is happy – it’s a win, win situation and everyone keeps moving forward in a positive direction. And should an injury occur, think positive that that will be the only injury for the year. Seize the opportunity to make it an educational, learning or training process. Investigate and see “why” the injury occurred and take “positive” steps to avoid the same thing occurring again. A positive attitude can be contagious!

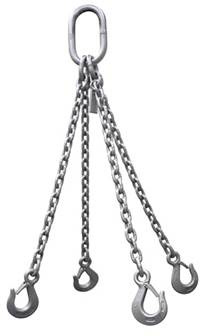

Will the angle of the rigging devise take away any of the cranes capacity?

Will the angle of the rigging devise take away any of the cranes capacity?

MIOSHA has reported 9 fatalities that have occurred in 2016 so far, 7 of them were from a “fall”. That would equate to approximately one fatality per month. I know we are a good sized state, but I think that is a high number, particularly in this day and age when we are so much more aware, informed and safety conscious.

MIOSHA has reported 9 fatalities that have occurred in 2016 so far, 7 of them were from a “fall”. That would equate to approximately one fatality per month. I know we are a good sized state, but I think that is a high number, particularly in this day and age when we are so much more aware, informed and safety conscious.