By Donna Motley, Vice President of Claims

It is that time of year again! Spring! Even though it is dark and raining outside as I write this, the calendar indicates the first day of Spring was on March 20th this year. While the weather may not seem like Spring has arrived, the school year is coming to an end.

Senior graduation, prom and graduation parties. At this time of year, students eligible to work between the ages of 14 and 17, legally known as a “minor”, may start looking for employment. This can be a win-win situation for both the minor and the prospective employer.

The minor may only be seeking “part-time” work and the employer may only need “part-time” help. Employers in the tooling industry are looking for ways to interest young people to learn manufacturing and maybe a skilled trade. It is not uncommon for minors to work within the fast food or retail industries, however, those positions can involve evenings and weekends. Clerical positions are generally 8 to 5:00. Whatever the position available for a minor, there are certain parameters that must be followed.

(more…)By Donna Motley, Vice President of Claims

At this time of year, particularly this year, we seem to talk and complain about the weather. The winter season 2018 – 2019 has been confusing, if nothing else. We’ve had snow, ice, sleet/freezing rain, temperatures that range from sub-zero to almost spring. As a result of our yo-yo weather, a lot of people have gotten sick and a lot of people have sustained an injury. Our department is receiving a lot of claims for “slip and fall on ice and snow” resulting in broken bones, sore muscles and head injuries that are being defined as a “concussion”. A concussion is considered to be a “traumatic brain injury” – a mild traumatic brain injury – the least serious type of brain injury. A concussion is defined as a short loss of normal brain function.

(more…)In January we mailed out information relating to Proposal 1 – Michigan Regulation & Taxation of Marihuana Act Passage. We mentioned that we were in the process of putting together a template for a substance abuse policy and that process is almost complete. It has gone a little slower than anticipated but should be in your hands in the next few weeks. For more information, please contact Megan Brown at (248) 715-0012 or your loss control representative.

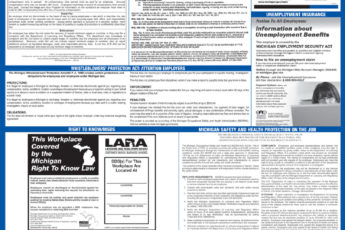

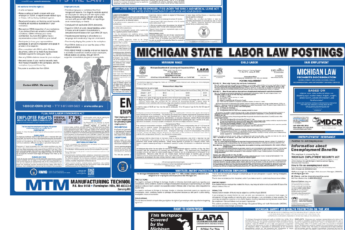

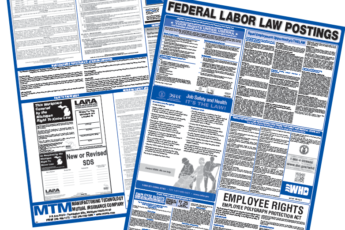

All State & Federal Labor Law Posters have been mailed out to all of our companies, as well as updated minimum wage information and the new Paid Medical Leave Act details. If you have NOT received yours please contact Patty Allen (patricia.allen@mtmic.com/blog) who will get a replacement set mailed out to you.

By Travis Halsted, Loss Control Consultant

Election Day 2018 has come and gone. A new governor was elected and several important issues were settled. While each item that was voted on holds a level of significance to many, one particular item has left companies from every industry scratching their heads. Proposal 1’s passage has provided more questions than answers, but I hope that I can help clear up some of the questions that you may have. Although Michigan voters passed the proposal to legalize marihuana for adult recreational use, employers can still “just say no” to hiring or retaining employees who violate workplace drug policies. The spelling of Marihuana versus the more common marijuana spelling dates back to the Marihuana Tax Act of 1937. Michigan utilized the federal spelling at that time, which was Marihuana. An act of Michigan Legislature is required in order to change the spelling to the informal spelling (marijuana), administrative rules will be using an “h” in the spelling.

(more…)The bill regarding Michigan’s Minimum Wage was just signed by the Governor on December 13, 2018. The new legislation is under review by the Department’s Wage and Hour Division. Therefore, the MTMIC State and Federal Labor Law Posters will not be mailed out in December as in past years due to the late changes made on the Michigan Minimum Wage section. We are waiting for updated information from LARA’s Wage and Hour Division. Unfortunately we have been told that the updated information will not be released until January. We apologize for the delay ~ posters will be sent as soon as we receive the updated information.

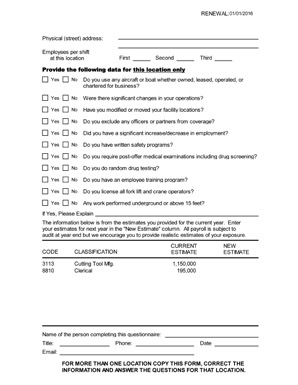

Payroll renewal forms have been sent out to all insureds that have an effective date in January 2019. We are asking for your estimated annual payroll for 2019 which assists in reducing the chance for additional audit money due at the end of your policy. Please complete

the form and return it to Glenda Moyle or an additional copy can be requested at glenda.moyle@mtmic.com/blog.

By Chris Demeter, Senior Loss Control Consultant

Every year, workers are unnecessarily exposed to hazardous energy sources such as mechanical, hydraulic, pneumatic, chemical, thermal, gravity, or other energies utilized by machines in manufacturing. This occurs during servicing, maintenance, or setting up on equipment. Accidental start-up of machinery or unintended release of stored energy often presents catastrophic risks including but not limited to crush, amputation, shock, and burn injuries as well as equipment damage. This exposure can cause serious physical injuries or death to workers unaware that someone else has started a machine or energized a circuit. MIOSHA requires employers to establish a Lockout-Tagout program and use procedures for affixing appropriate lockout devices or tag out devices to energy isolating devices, and to otherwise disable machines or equipment to prevent unexpected re-energizing, start up or release of stored energy in order to prevent injury to employees.

This is a time of year when we see many MTM member requests for a certificate of insurance or waiver of subrogation. Many of our shop members never need either of these items. However, if your shop does installation work of a product or is often at a customer’s plant location, you know full well about the use of these two documents. This year we’ve seen an uptick in the number of members that request these forms and thought it was a good time to review for all of MTM members.For a global perspective on these documents, you need to know that these are documents requested by customers of our MTM members. Neither document provides coverage for the MTM member, but rather it provides coverage certainty to the MTM customers. In the case of the certificate of insurance, if your worker is at a customer’s location and gets injured, the customer wants to know that you have workers’ compensation coverage. The customer does not want to “inherit” the injured worker’s claims costs. Similarly, for your shop if you hire a company to work at your plant and an employee of the hired company is hurt, does that company you hired have workers’ compensation coverage? If not, that loss most often moves to the next employer in line, which would be the MTM member. This “ladder” of coverage for workers’ comp was intended to find coverage for an injured worker. If his direct employer is not covered, then the system works up the ladder until coverage is found. With a certificate of insurance, you are getting certainty that an injured worker will be covered by his employer.

By Glenda Moyle, Premium Accounting Manager

This is just a reminder that our auditing company, The Aprise Group will be completing the final audits for all MTMIC policyholders again this year. We have had a partnership with The Aprise Group for the past 25+ years. Once your policy expires, The Aprise Group will be contacting you within 30 days to set up an appointment to complete your audit. If you have any questions, please contact me at glenda.moyle@mtmic.com/blog or (248) 715-0015. Thank you for being a member of MTMIC.

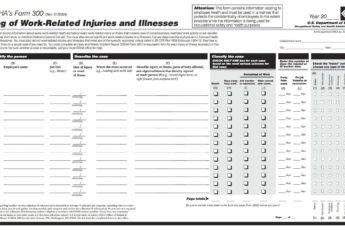

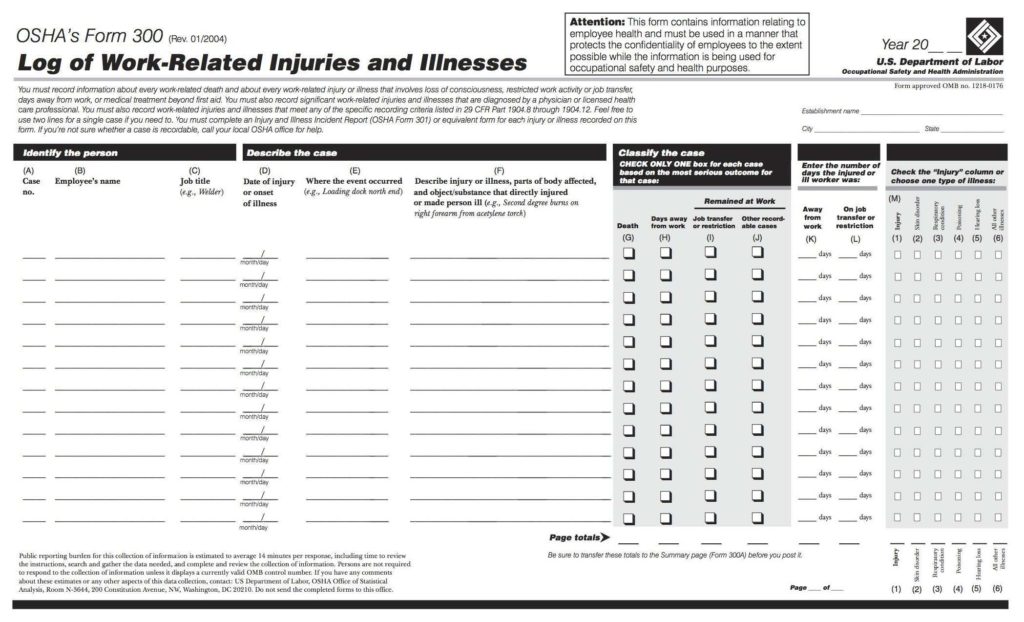

2017 OSHA Injury Tracking of Electronic Submission of Injury and Illness Records

By Ruth Kiefer, Loss Control Manager, MSc, ARM

As I know many of you have just finished submitting your 2016 injury data that was either submitted on a 300A or 300 injury log onto the OHSA website this past December. But I want to remind you that you will also need to submit your 2017 injury data as well. If you are a covered establishment (determined by your NAICS code), you may start submitting either the 300 or 300A now through April 1, 2018.

Updated sets of the State and Federal Labor Law posters have been mailed out to all current policyholders. If you have any questions or need additional sets please contact Patty Allen at patricia.allen@mtmic.com/blog or (248) 715-0013.

By Donna Motley, Vice President of Claims

As your Workers’ Compensation carrier, we provide a service. Hopefully, part of that service is to make your job a little easier. In today’s world, everyone is busy. We can help take some tasks off your shoulders. After a work related injury, we can contact the doctor’s office or medical facility and provide the insurance and/or claim information. Any authorization to treat, refer for testing or to another physician, should be provided by our department pursuant to the Workers’ Compensation Act and Michigan Health Care Services Rules. We can contact the injured worker and relay necessary information; and answer the employee’s questions as to “how does this (the compensation process) work”?

In order for us to help “you”, we need you to help “us”. The first and best way to aid in the Workers’ Compensation process is to promptly report the injury to us. The second best way, is to make sure we have complete and detailed information. While I realize sometimes the Employer’s Basic Report of Injury (Form 100) has to be completed in haste, the more information provided, the least likely we are to call or e-mail you with questions or requests for additional information. Please realize, when detailing “how” an injury occurred, what may make perfect sense to you may raise additional questions in our minds. We are not necessarily familiar with your facility, the employee’s work duties, work process, the machines on site or how they operate.

SHA is not accepting electronic submissions of injury and illness logs at this time. According to their website, they are extending the July 1, 2017 date by which certain employers are required to electronically submit the information from their completed 2016 Form 300A. Updates will be posted to the following OSHA webpage when they are available.

https://www.osha.gov/injuryreporting/index.html

By Donna Motley, Vice President of Claims

What is entailed in processing a Workers’ Compensation injury claim? Once the claim form is submitted and set up in our system, it is more than just processing and paying the medical bills. In most cases the injured worker is treating with the employer’s Occupational Clinic. It is the Claims Adjusters’ responsibility to assure the employee is receiving proper treatment, with the appropriate medical personnel; and if necessary, have treatment of the injured worker transferred to a physician specializing in said injury. Orthopedic physicians specialize – back, shoulder, knee, foot, elbow, hands, etc. A mucular condition would be referred to a Physiatrist.

We monitor each and every doctor appointment the employee attends. If an appointment is missed or rescheduled, we want to know why. We follow up for the necessary disability slip the injured is required to submit to their employer.

With spring weather finally arriving, many companies are now hiring summer interns or have youth employment. There are some tricky pieces to young employment that are worth sharing with you. First be advised or warned that youth employment rules are strictly enforced. Regulators take great care of providing an extra layer of protection for employees under 18 years old. Let me cover some of the restrictions that apply to employees under 18. The law is clear about occupational duties that are restricted based on age. Employees under the age of 18 are prohibited from working in ANY hazardous or injurious occupation. The regulations then specify some of the items included in their hazardous or injurious tasks: driving, working power equipment, exposure to hazardous substances or chemicals, driving hoisting apparatus such as lift trucks or Bobcats, running any power driven metal forming, punching, or shearing machines, running circular saws or band saws or involvement in any building maintenance such as roofing or painting.

There is a narrow exception of some of the above tasks. The exceptions are permitted in order for students to be enrolled in state approved career or technical education training or apprentice programs. They must be specifically approved and documented.

The Michigan child labor laws also require adult supervision for any employee under 18 years of age. These rules become even more strict if the employee is under the age of 16. The good news for the summer is that the many rules dealing with limited hours during the school year are not a factor. But just a red flag for the rest of the year, the child labor laws are very specific to make sure that the hours are limited and do not infringe upon youth school activities.

At the beginning of this topic I mentioned regulator enforcement is aggressive and punishment for violations is significant and severe. A first violation is imprisonment for one year, and a fine of $2,000. A second violation is a $10,000 fine and 10 years of imprisonment. The Department of Labor takes seriously their role in requiring safe environment for employees under the age of 18.

Even with these restrictions, student interns are a helpful resource and a benefit for both the company and the youth employee. At MTM we use interns to help us with mass mailings, filing, and other office duties. The youth gets to build some experience for their first resume and the company gets some tasks taken care of that are difficult to accomplish during the regular business day. I expect that our member shops have seen the same rewards for both their company and for their kids that are involved.

If you run across a question on this, please do not hesitate to contact us and we can go over it in more detail with you. The law is four pages, single-spaced, we are happy to share that with you for those that are interested. Until next month, I hope you enjoy the spring weather and we will get ready for the warm days just around the corner.

By Ruth Kiefer, Loss Control Manager, MSc, ARM

As our economy is ramping back up, and our facilities are becoming busy again, the decision to hire permanent workers or use temporary workers is a factor that you must debate. When reviewing this decision, you should be aware of MIOSHA’s new initiative regarding temporary workers and what your responsibilities are as an employer.

MiOSHA considers both host employers and staffing agencies are responsible to comply with the workplace health and safety requirements. The key is to ensure that the staffing agency has conducted a general safety and health training to determine what is missing. The host employer is responsible for providing specific training tailored to the particular workplace hazard or equipment operation. The key is communication between both the agency you’re working with and you the host employer to ensure that the necessary training is provided.

By Donna Motley, Vice President of Claims

Does your employee know what to do if they sustain a work related injury? Whether your employee is a new hire or has worked at your facility for many years, the procedure is the same. All employees should be briefed upon hire of the steps to be taken should a work injury occur. Employees should be reminded periodically, no less than annually, of proper procedures or any changes in said procedures, should an injury occur. All employees, not just the injured person, play a part in work safety. All employees should be diligent in keeping the work environment clean; clean up or report oil spills, report unsafe practices, report faulty equipment and safety hazards. A co-worker may be a witness to an injury.

By Ruth Kiefer, Loss Control Manager, MSc, ARM

As you know one of the nerve-racking issues of keeping up with the MIOSHA safety standards is when a compliance officer comes to visit and puts your safety efforts to the test. Their visits can be spurred by an employee complaint, your industry code being on their strategic plan, or a visit that results from a severe injury. A recent visit in December of 2016, to a manufacturing plant in Ypsilanti, resulted in $265,600 in fines. The MIOSHA inspector found eight serious, six repeat serious, and three other-than-serious safety violations that were noted during the visit. The safety standards that were in violation were the same things that were on our April’s edition of MIOSHA’s top 10 safety violations. The list of standards found in violation included: